Frank J. Wood Bridge Project

Frank J. Wood Bridge Project

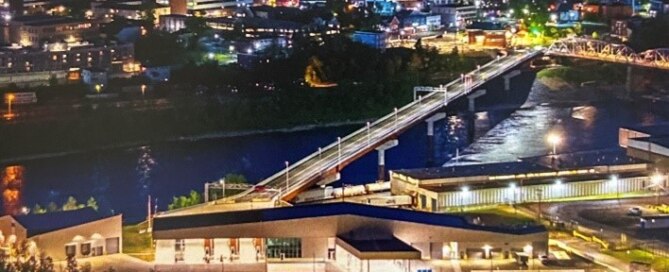

The Frank J. Wood Bridge between the towns of Brunswick and Topsham made great progress this fall in preparation for steel erection this winter.

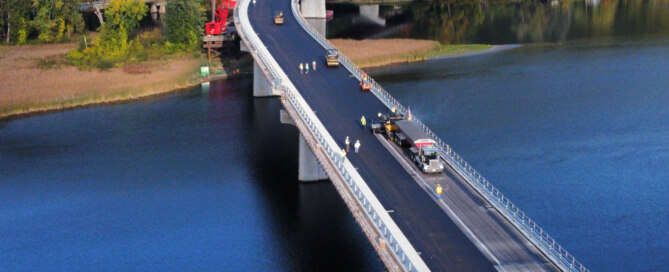

After the challenging floods of January 2024, the crew hit the water in August to knock out cofferdams at Piers 1 & 2. Not the easiest of cofferdams to build as they were sitting directly on exposed ledge just below the dam, but the crew made quick work of them to make way for pier construction. Meanwhile another crew was wrapping up construction of Abutment 1 and reconfiguring forms & liner to hit the two remaining piers full steam.

Currently the bridge substructure is complete, and steel erection is well underway with giant steel girders arriving each week from Pennsylvania. The curved girders vary in length and weight, ranging up to 119 feet and 95,000 pounds. With completion of steel erection wrapping up before spring, crews will begin building the bridge deck formwork in preparation for installing the concrete deck later in 2025.

Despite the winter conditions, Reed & Reed crews and the faithful spectators from Brunswick and Topsham are on hand daily!