Oakfield Wind Project

The Oakfield, Maine wind power project achieved COD right on schedule in fall 2015 despite the unusually harsh 2015 Maine winter. At 148 mw, this project eclipses the 132 mw Kibby, Maine Wind Power project, also built by Reed & Reed, as New England’s largest wind power project.

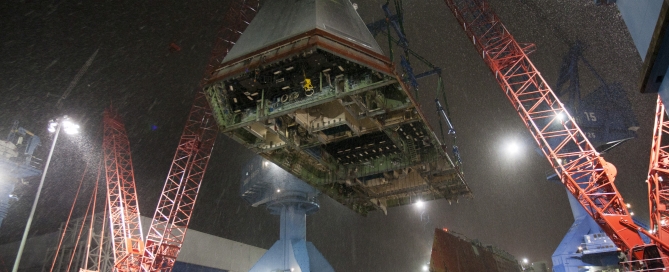

Major project elements in Reed & Reed’s contract included expanding the Keane Road substation in Chester, constructing a 58 mile 115kv transmission line, building 48 wind turbine foundations, installing electrical collector systems, a new project substation, O&M building and of course erection of the 48 Vestas V-112 wind turbines.

The 58 mile 115kv transmission line connecting the Oakfield collector substation to the Keene Road substation expansion was energized in May 2015.

The project’s collector, collector substation, synchronous condenser and O&M building installations, with circuits being energized sequentially to facilitating turbine commissioning, were all completed on time and under budget.

Reed & Reed is proud to have completed this project safely, on time and under budget with its Maine-based workforce.